Ventiladores axiales y centrífugos

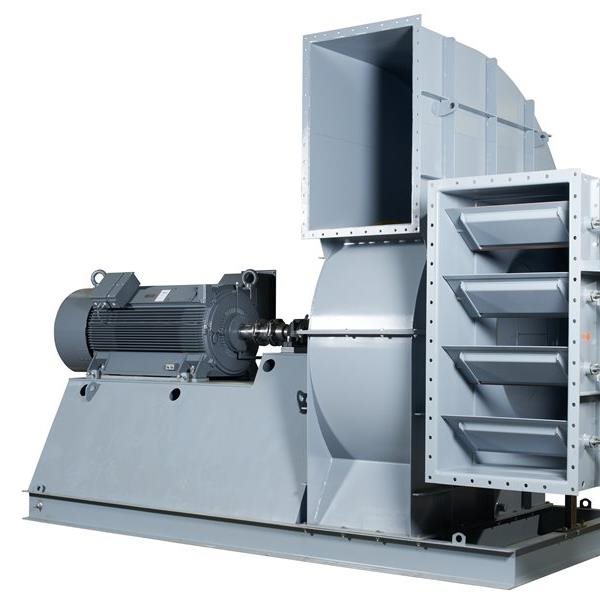

Los ventiladores axiales y centrífugos altamente eficientes y confiables de Howden admiten una amplia gama de procesos industriales que requieren el flujo de aire o gas.

Howden diseña ventiladores para satisfacer las demandas industriales desde hace más de 100 años y continúa liderando el mundo en cuanto a aumentar la eficiencia energética, mejorar la fiabilidad y reducir los costos de por vida para nuestros clientes. Howden tiene un ventilador a la medida de la aplicación, ya sea en posiciones críticas en procesos industriales pesados o aplicaciones auxiliares dentro de la industria ligera.

El aire es uno de los ingredientes más comunes de los procesos industriales y los ventiladores de Howden han sido parte integral de dichos procesos desde la revolución industrial.

Nuestros ventiladores pueden utilizarse como corriente forzada o inducida para aspirar o empujar volúmenes específicos de aire a través del proceso. Se adaptan a una amplia gama de volúmenes y presiones, y ofrecen un rendimiento confiable para garantizar una producción continua.

Objetivo: proporcionar caudales de aire confiables a volúmenes y presiones seleccionados en cada etapa del proceso con la más alta eficiencia.

Procesos típicos a los que se presta servicio

Las industrias a las que servimos manejan muchos tipos de gases dentro de los procesos de producción y también como subproducto del proceso.

Nuestros ventiladores son centrales para los procesos continuos que tratan gases, desde nitrógeno, hidrógeno y gases nobles hasta gases residuales. Están diseñados para ser duraderos y ofrecer un alto rendimiento, resistiendo los efectos de los gases corrosivos, al tiempo que sellan el gas de forma segura dentro del ventilador y el proceso.

Objetivo: transportar de forma segura y eficiente caudales de gas a volúmenes y presiones seleccionados dentro y desde cada proceso.

Procesos típicos a los que se presta servicioHowden también cuenta con una serie de compresores de gas en caso de que los requisitos de caudal y presión de gas superen los adecuados para nuestros ventiladores.

Confíe en que los ventiladores Howden mantendrán condiciones seguras y cómodas para el trabajo y el transporte, ya sea dentro de instalaciones industriales o bajo tierra.

Nuestros ventiladores aspiran o empujan grandes volúmenes de aire a través del sistema de ventilación, además de extraer aire residual, gases y potencialmente humo de espacios protegidos.

Objetivo: mover los caudales de aire requeridos dentro del sistema con eficiencia de manera continua y durante una emergencia.

Procesos típicos a los que se presta servicio

Los ventiladores Howden son una parte vital de los sistemas de enfriamiento de procesos y de servicios públicos que utilizan aire para disipar el calor a la atmósfera. Nuestros productos son reconocidos por su excelente eficiencia y bajo nivel de ruido, lo que permite a los operadores diseñar la mejor solución en relación con los requisitos de capacidad de enfriamiento, el espacio en el emplazamiento y la normativa sobre ruido.

Nuestros ventiladores aspiran o empujan grandes volúmenes de aire a través de intercambiadores de calor refrigerados por aire (air cooled heat exchangers, ACHE/ACHX), condensadores refrigerados por aire (air cooled condensers, ACC) y torres de enfriamiento. También se utilizan dentro de maquinaria pesada para mantener los motores a temperaturas de funcionamiento óptimas.

Objetivo: extraer el calor de un proceso u operar el equipo con eficiencia y dentro de los límites de ruido permitidos.

Procesos típicos a los que se presta servicio

El aire es uno de los ingredientes más comunes de los procesos industriales y los ventiladores de Howden han sido parte integral de dichos procesos desde la revolución industrial.

Nuestros ventiladores pueden utilizarse como corriente forzada o inducida para aspirar o empujar volúmenes específicos de aire a través del proceso. Se adaptan a una amplia gama de volúmenes y presiones, y ofrecen un rendimiento confiable para garantizar una producción continua.

Objetivo: proporcionar caudales de aire confiables a volúmenes y presiones seleccionados en cada etapa del proceso con la más alta eficiencia.

Procesos típicos a los que se presta servicio

Las industrias a las que servimos manejan muchos tipos de gases dentro de los procesos de producción y también como subproducto del proceso.

Nuestros ventiladores son centrales para los procesos continuos que tratan gases, desde nitrógeno, hidrógeno y gases nobles hasta gases residuales. Están diseñados para ser duraderos y ofrecer un alto rendimiento, resistiendo los efectos de los gases corrosivos, al tiempo que sellan el gas de forma segura dentro del ventilador y el proceso.

Objetivo: transportar de forma segura y eficiente caudales de gas a volúmenes y presiones seleccionados dentro y desde cada proceso.

Procesos típicos a los que se presta servicioHowden también cuenta con una serie de compresores de gas en caso de que los requisitos de caudal y presión de gas superen los adecuados para nuestros ventiladores.

Confíe en que los ventiladores Howden mantendrán condiciones seguras y cómodas para el trabajo y el transporte, ya sea dentro de instalaciones industriales o bajo tierra.

Nuestros ventiladores aspiran o empujan grandes volúmenes de aire a través del sistema de ventilación, además de extraer aire residual, gases y potencialmente humo de espacios protegidos.

Objetivo: mover los caudales de aire requeridos dentro del sistema con eficiencia de manera continua y durante una emergencia.

Procesos típicos a los que se presta servicio

Los ventiladores Howden son una parte vital de los sistemas de enfriamiento de procesos y de servicios públicos que utilizan aire para disipar el calor a la atmósfera. Nuestros productos son reconocidos por su excelente eficiencia y bajo nivel de ruido, lo que permite a los operadores diseñar la mejor solución en relación con los requisitos de capacidad de enfriamiento, el espacio en el emplazamiento y la normativa sobre ruido.

Nuestros ventiladores aspiran o empujan grandes volúmenes de aire a través de intercambiadores de calor refrigerados por aire (air cooled heat exchangers, ACHE/ACHX), condensadores refrigerados por aire (air cooled condensers, ACC) y torres de enfriamiento. También se utilizan dentro de maquinaria pesada para mantener los motores a temperaturas de funcionamiento óptimas.

Objetivo: extraer el calor de un proceso u operar el equipo con eficiencia y dentro de los límites de ruido permitidos.

Procesos típicos a los que se presta servicio

Howden tiene una trayectoria de ingeniería de ventiladores desarrollada a lo largo de cientos de años a través de la marca original Howden y aquellas que se unieron a la empresa, como Sirocco, Sturtevant, Buffalo Forge, Covent, Turbowerke Meissen, Solyvent-Ventec, Voith y Nordisk.

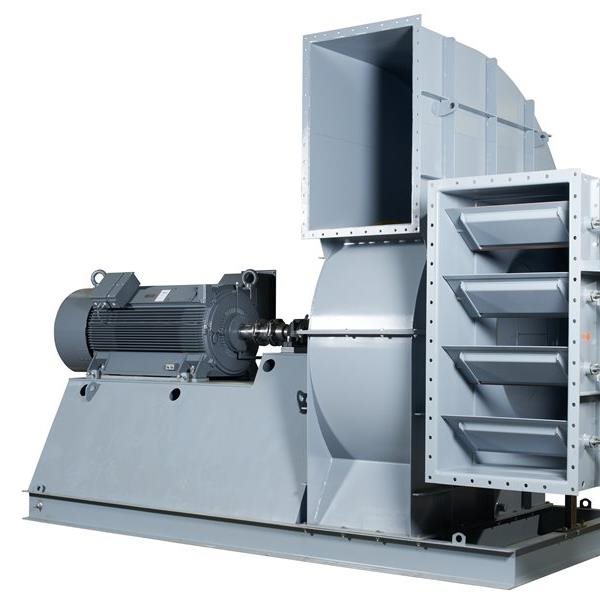

Nuestros ventiladores van desde configurados hasta completamente diseñados para satisfacer una amplia variedad de demandas de los clientes. Nuestra capacidad de ingeniería significa que podemos tener el conocimiento, la experiencia y la capacidad de adaptar y desarrollar nuevos diseños para requisitos específicos.

Todos los ventiladores están diseñados para maximizar el funcionamiento eficiente, con algunos que alcanzan más del 90 %, según la aplicación y el funcionamiento. Los ventiladores cumplen los estándares de la industria según se requiera para cada aplicación, p. ej., certificaciones conforme a la norma API, la clasificación ATEX o el sector de energía nuclear.

Gama de productos

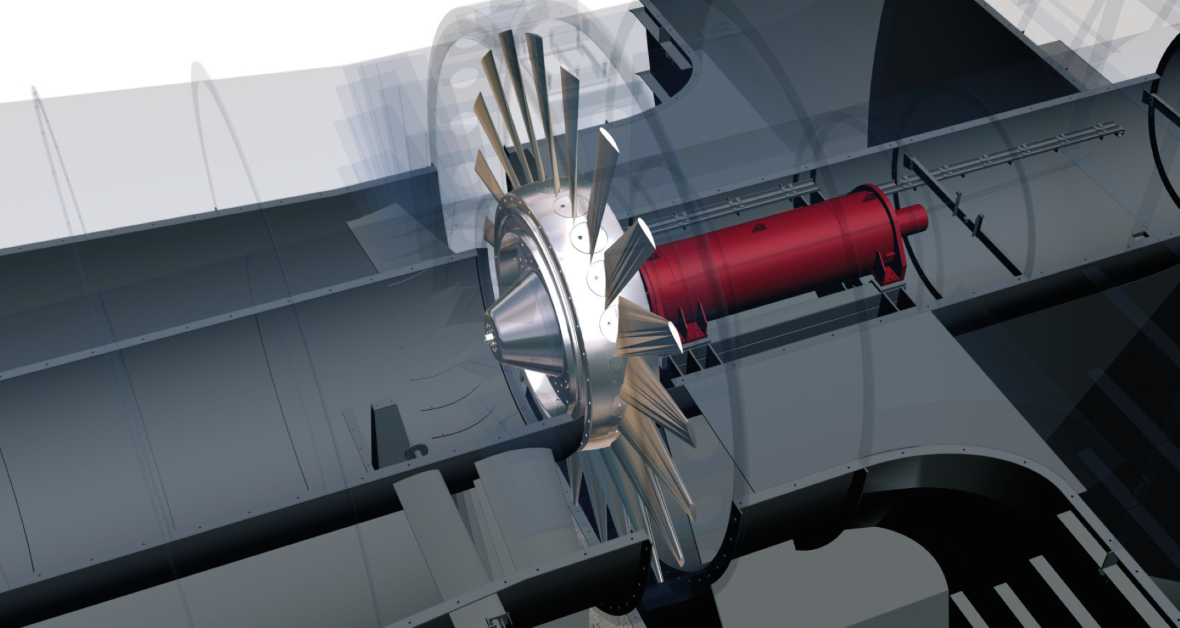

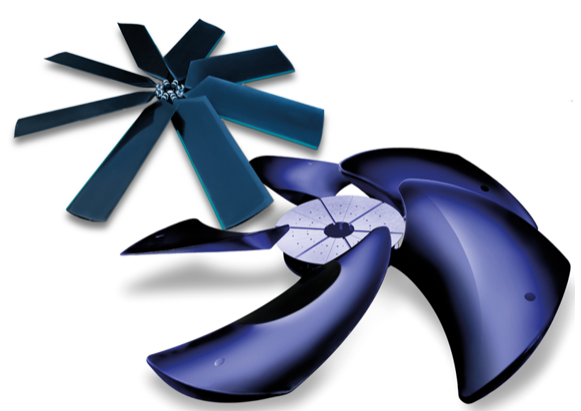

La gama de ventiladores axiales incluye una gama de productos desarrollados a través de una serie de marcas actuales y heredadas de Howden para ofrecer una cobertura integral de los requisitos de caudal y presión industriales.

Esta gama nos permite abordar numerosas aplicaciones con configuraciones alternativas de colocación vertical u horizontal y diferentes opciones de control de caudal, desde paso ajustable manualmente hasta paso variable y variadores de frecuencia.

Todos los ventiladores se fabrican con altos estándares para un funcionamiento eficiente y bajo mantenimiento a través de un servicio confiable.

Gama de productos

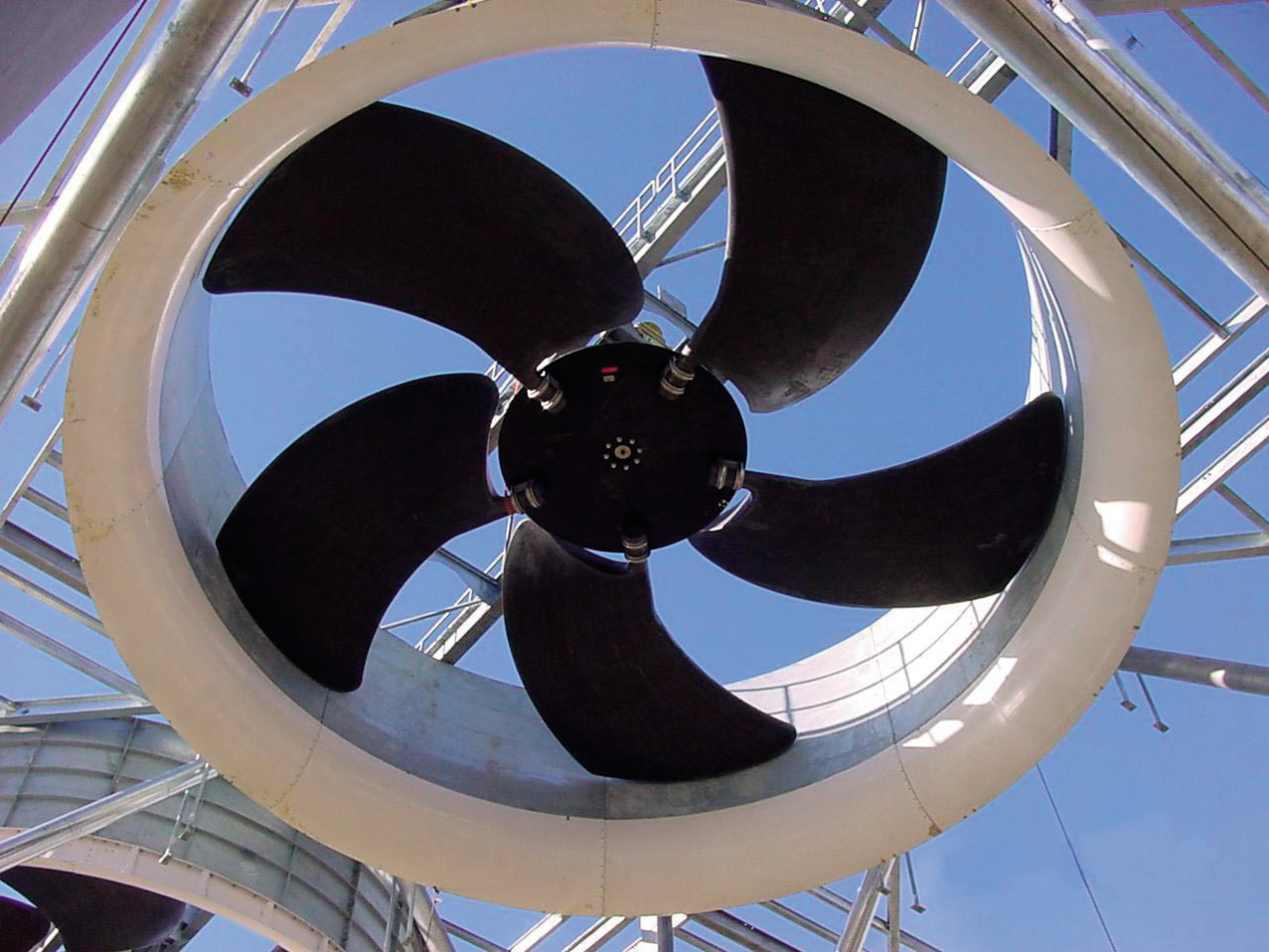

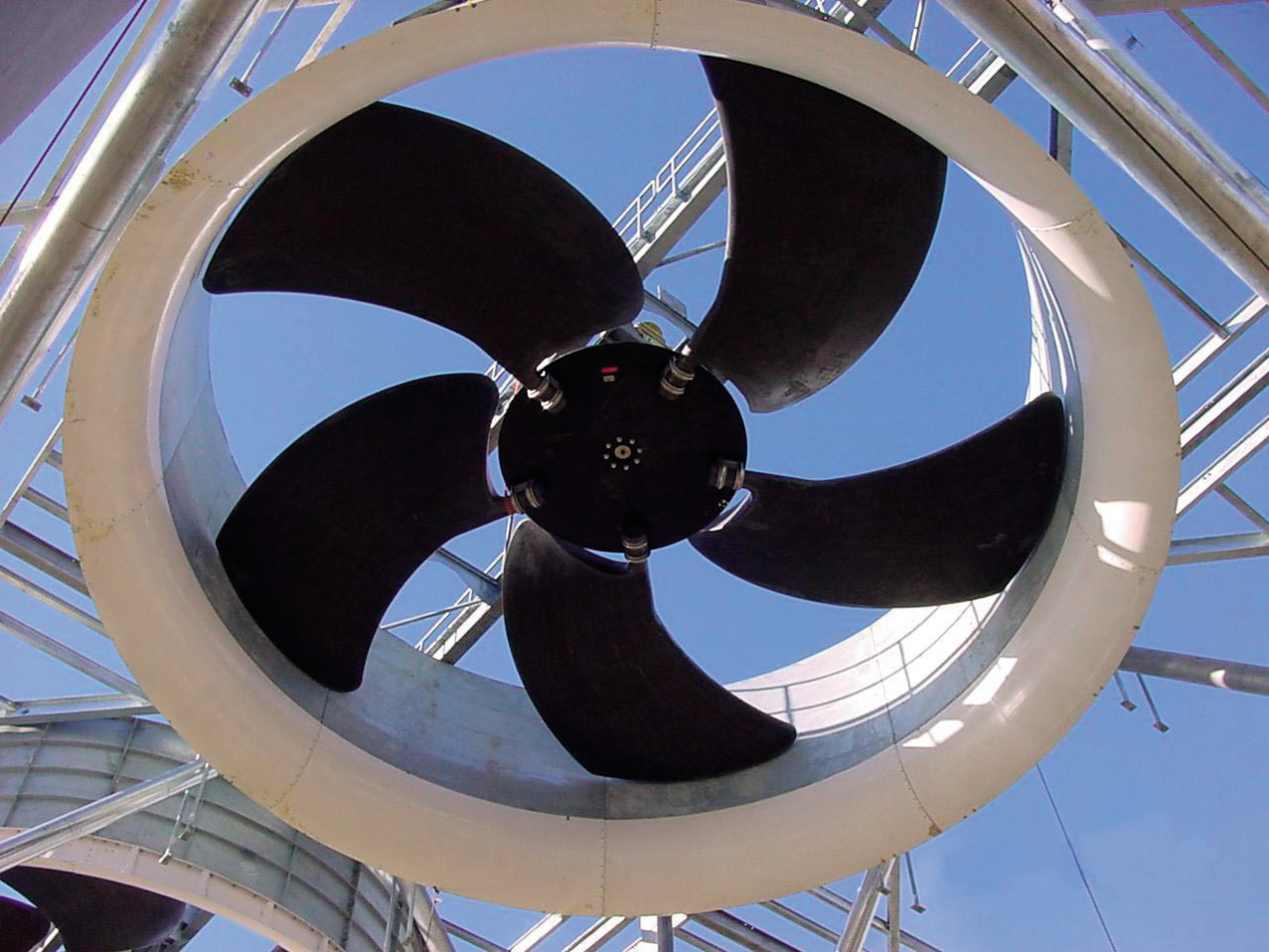

Nuestra gama de ventiladores de enfriamiento consta de las series D, E, SX y FPX, y ofrece un rendimiento excepcional en eficiencia y niveles de ruido en un conjunto diverso de industrias, desde plantas de petróleo y gas, plantas de energía hasta plantas de fabricación industriales ligeras, centros de datos, edificios comerciales y motores de maquinaria industrial.

La gama de ventiladores abarca una amplia zona de rendimiento con una baja caída de presión de hasta 250 Pa y un alto volumen de flujo de aire de hasta 3000 m³/s. Ofrecen capacidades de ruido bajo a ultrabajo para maximizar el rendimiento dentro de las regulaciones del emplazamiento.

Para obtener más información sobre la gama, visite nuestra página de productos de ventiladores de enfriamiento y acceda a nuestros materiales de marketing.

Nuestros ventiladores van desde configurados hasta completamente diseñados para satisfacer una amplia variedad de demandas de los clientes. Nuestra capacidad de ingeniería significa que podemos tener el conocimiento, la experiencia y la capacidad de adaptar y desarrollar nuevos diseños para requisitos específicos.

Todos los ventiladores están diseñados para maximizar el funcionamiento eficiente, con algunos que alcanzan más del 90 %, según la aplicación y el funcionamiento. Los ventiladores cumplen los estándares de la industria según se requiera para cada aplicación, p. ej., certificaciones conforme a la norma API, la clasificación ATEX o el sector de energía nuclear.

Gama de productos

La gama de ventiladores axiales incluye una gama de productos desarrollados a través de una serie de marcas actuales y heredadas de Howden para ofrecer una cobertura integral de los requisitos de caudal y presión industriales.

Esta gama nos permite abordar numerosas aplicaciones con configuraciones alternativas de colocación vertical u horizontal y diferentes opciones de control de caudal, desde paso ajustable manualmente hasta paso variable y variadores de frecuencia.

Todos los ventiladores se fabrican con altos estándares para un funcionamiento eficiente y bajo mantenimiento a través de un servicio confiable.

Gama de productos

Nuestra gama de ventiladores de enfriamiento consta de las series D, E, SX y FPX, y ofrece un rendimiento excepcional en eficiencia y niveles de ruido en un conjunto diverso de industrias, desde plantas de petróleo y gas, plantas de energía hasta plantas de fabricación industriales ligeras, centros de datos, edificios comerciales y motores de maquinaria industrial.

La gama de ventiladores abarca una amplia zona de rendimiento con una baja caída de presión de hasta 250 Pa y un alto volumen de flujo de aire de hasta 3000 m³/s. Ofrecen capacidades de ruido bajo a ultrabajo para maximizar el rendimiento dentro de las regulaciones del emplazamiento.

Para obtener más información sobre la gama, visite nuestra página de productos de ventiladores de enfriamiento y acceda a nuestros materiales de marketing.

Nuestra capacidad de servicio abarca todos los ventiladores axiales, desde sus propias marcas hasta las de otros fabricantes.

Para las marcas de ventiladores propias, ofrecemos una gama completa de soluciones de mercado de accesorios, desde piezas de repuesto OEM, análisis y resolución de problemas y mantenimiento general, hasta mejoras y adaptaciones completamente diseñadas para el rendimiento operativo y la extensión de la vida útil.

Nuestras marcas incluyen las marcas actualmente disponibles como equipos nuevos, como Howden y Alphair, pero también las adquiridas en el transcurso de nuestros 160 años de historia, que incluyen Buffalo Forge, Turbowerke Meisen y Nordisk.

Acceda a materiales de marketing disponibles

Teléfono +44 141 885 7500