Pulpa y papel

Desde el movimiento del aire por procesos esenciales hasta la recuperación de potencia y energía, Howden cuenta con el equipo para garantizar una producción continua confiable.

Tenemos raíces profundas en la industria de la pulpa y el papel con productos de ingeniería que se remontan a más de 140 años. Ya sea optimizando y manteniendo su equipo rotativo existente o introduciendo iniciativas de eficiencia energética, Howden está presente para respaldar la industria.

Puesto que es un proceso que consume mucha energía, la producción de pulpa y papel obtiene ventajas significativas con la adopción de métodos de recuperación de energía. La MVR también se utiliza para concentrar efluentes en lugares donde existen normas de tratamiento más estrictas.

Los turboventiladores de Howden se han utilizado durante mucho tiempo como parte de la evaporación del licor negro, devolviendo la energía de cada etapa al proceso a través de la recompresión mecánica de vapor. Con más de 50 plantas en Europa, América y Asia que utilizan nuestros ventiladores, hemos desarrollado una sólida experiencia en optimizar la eficiencia de los procesos. Los turboventiladores ExVel utilizados para MVR en estas plantas están procesando flujos de masa de hasta 200.000 kg/h y temperaturas de tratamiento de hasta 140 °C.

Nuestras turbinas de vapor también son centrales para la recuperación de energía porque convierten el calor residual producido en la fabricación de pulpa y papel en energía eléctrica.

Nuestras turbinas de vapor se utilizan ampliamente con configuraciones de energía industrial a pequeña escala, como plantas de pulpa y papel.

La gama Howden se basa en reconocidas marcas de turbinas de vapor de Kühnle, Kopp y Kausch (KK&K) y Peter Brotherhood. Estas turbinas tienen una salida de potencia de hasta 40 MW y se pueden suministrar con una configuración diferente para adaptarse a la potencia o también a la extracción para otros usos de vapor.

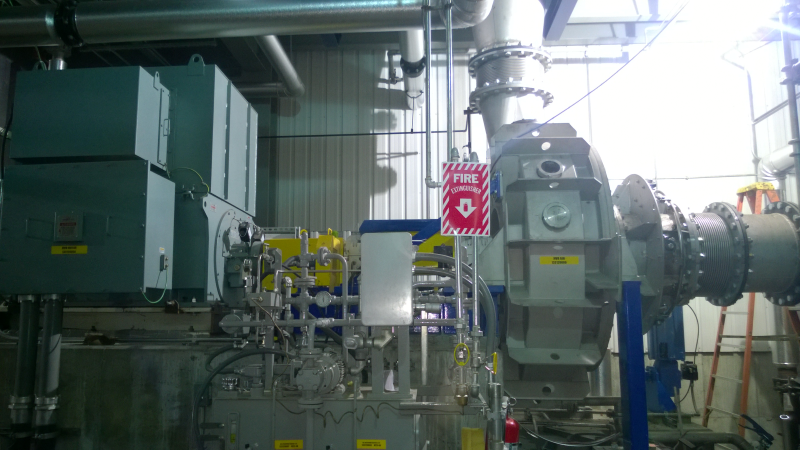

Howden puede proporcionar ventiladores para cada aplicación en la industria del papel con más de 25.000 instalados en plantas y fábricas en todo el mundo.

Nuestros ventiladores se adaptan a todas las aplicaciones en la industria del papel gracias a su enfoque de diseño flexible y rentable. Espere eficiencia operativa con ventiladores Howden incluso en entornos con secadores de alta presión, cargados de gas y corrosivos.

Los usos típicos implican procesos en los que se requiere una construcción resistente a la corrosión. Las máquinas de papel requieren equipos de ventiladores para secadores de alta presión y calentadores. Nuestros ventiladores para la industria del papel pueden recubrirse o tener una construcción de acero inoxidable. Howden puede proporcionar un ventilador para sistemas ambientales, así como para la remoción de partículas, humos y olores, que son aplicaciones típicas para la industria del papel.

AplicacionesNuestra familia de marcas incluye Buffalo Forge, Flygt, Covent, Canadian Blower, Solyvent Ventec, TLT-Babcock, Alphair, entre otras.

Puesto que es un proceso que consume mucha energía, la producción de pulpa y papel obtiene ventajas significativas con la adopción de métodos de recuperación de energía.

Los turboventiladores de Howden se han utilizado durante mucho tiempo como parte de la evaporación del licor negro, devolviendo la energía de cada etapa al proceso a través de la recompresión mecánica de vapor. La MVR también se utiliza para concentrar efluentes en lugares donde existen normas de tratamiento más estrictas.

Con más de 50 plantas en Europa, América y Asia que utilizan nuestros ventiladores, hemos desarrollado una sólida experiencia en optimizar la eficiencia de los procesos. Los turboventiladores ExVel utilizados para MVR en estas plantas están procesando flujos de masa de hasta 200.000 kg/h y temperaturas de tratamiento de hasta 140 °C.

Nuestras turbinas de vapor también son centrales para la recuperación de energía porque convierten el calor residual producido en la fabricación de pulpa y papel en energía eléctrica.

Nuestras turbinas de vapor se utilizan ampliamente con configuraciones de energía industrial a pequeña escala, como plantas de pulpa y papel.

La gama Howden se basa en reconocidas marcas de turbinas de vapor de Kühnle, Kopp y Kausch (KK&K) y Peter Brotherhood. Estas turbinas tienen una salida de potencia de hasta 40 MW y se pueden suministrar con una configuración diferente para adaptarse a la potencia o también a la extracción para otros usos de vapor.

Howden puede proporcionar ventiladores para cada aplicación en la industria del papel con más de 25.000 instalados en plantas y fábricas en todo el mundo.

Nuestros ventiladores se adaptan a todas las aplicaciones en la industria del papel gracias a su enfoque de diseño flexible y rentable. Espere eficiencia operativa con ventiladores Howden incluso en entornos con secadores de alta presión, cargados de gas y corrosivos.

Los usos típicos implican procesos en los que se requiere una construcción resistente a la corrosión. Las máquinas de papel requieren equipos de ventiladores para secadores de alta presión y calentadores. Nuestros ventiladores para la industria del papel pueden recubrirse o tener una construcción de acero inoxidable. Howden puede proporcionar un ventilador para sistemas ambientales, así como para la remoción de partículas, humos y olores, que son aplicaciones típicas para la industria del papel.

AplicacionesNuestra familia de marcas incluye Buffalo Forge, Flygt, Covent, Canadian Blower, Solyvent Ventec, TLT-Babcock, Alphair, entre otras.

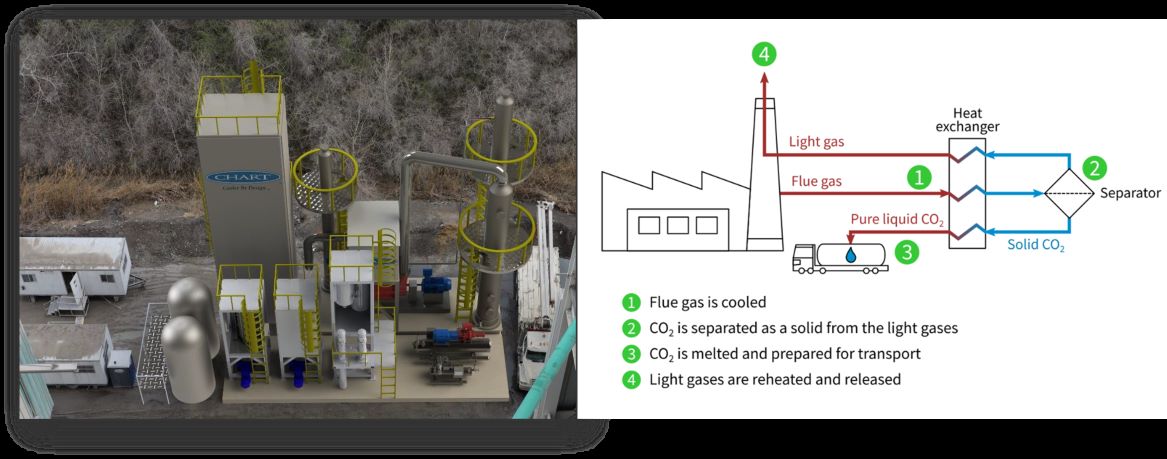

Chart proporciona sistemas adjuntos que pueden incorporarse para mejorar la sostenibilidad y descarbonizar la industria de la pulpa y el papel.

La captura criogénica de carbono (Cryogenic Carbon Capture, CCC) es un proceso posterior a la combustión que reduce el carbono y otras emisiones nocivas de gases de combustión. La CCC puede adaptarse en plantas existentes o incorporarse en diseños de nuevas plantas.

Para obtener más información, visite nuestra página web

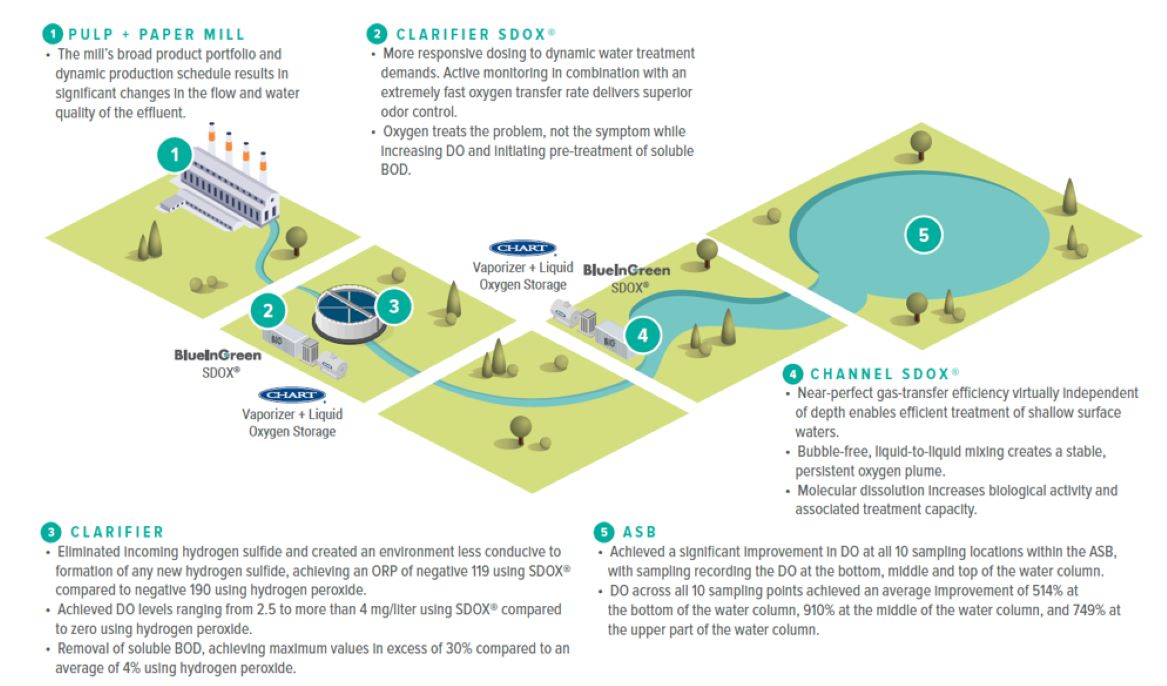

A través de ChartWater podemos ofrecer una amplia gama de tratamientos para aguas efluentes con el fin de garantizar que sus instalaciones siempre cumplan los más altos estándares ambientales.

Para obtener más información, visite nuestra página web

Teléfono +44 141 885 7500