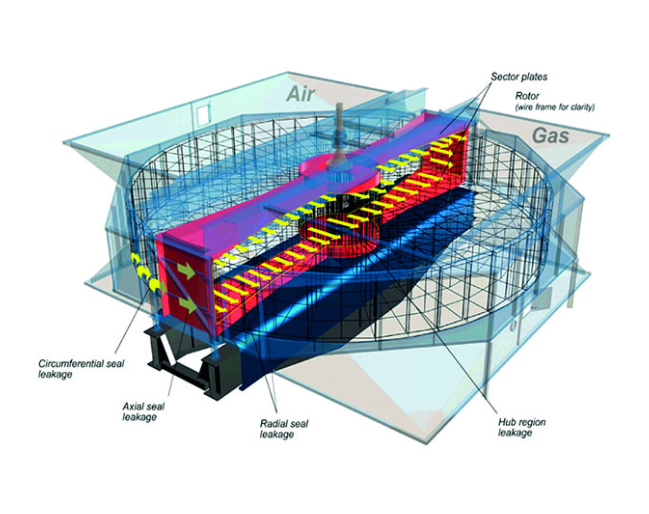

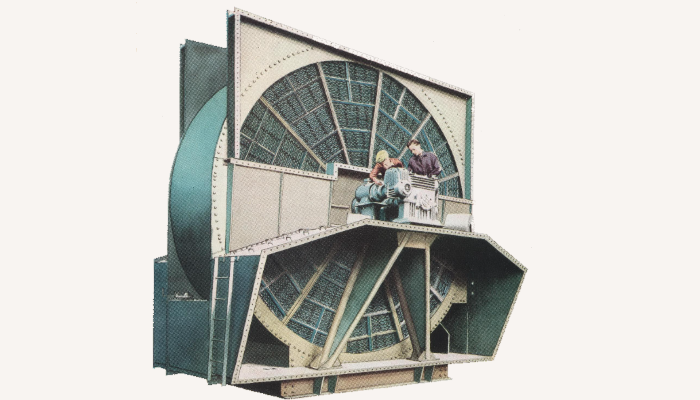

Sellado avanzado

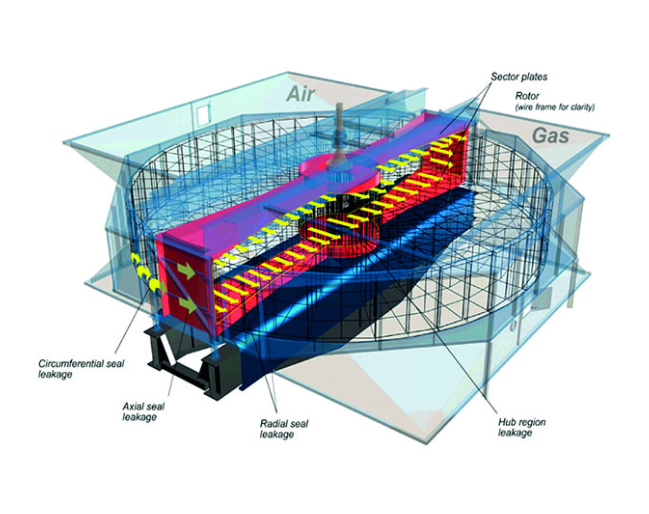

Minimizar las fugas de gas es una consideración clave y Howden ha desarrollado una serie de soluciones innovadoras.

El sistema de sellado VN mantiene un nivel de fugas constantemente bajo durante períodos prolongados. Se adoptan métodos adicionales para los GGH, como presurizar el espacio de sellado con gas limpio, con un ventilador de purga para crear una ligera diferencia de presión. Luego, un sistema de barrido expulsa gas sucio de los elementos utilizando gas tratado.

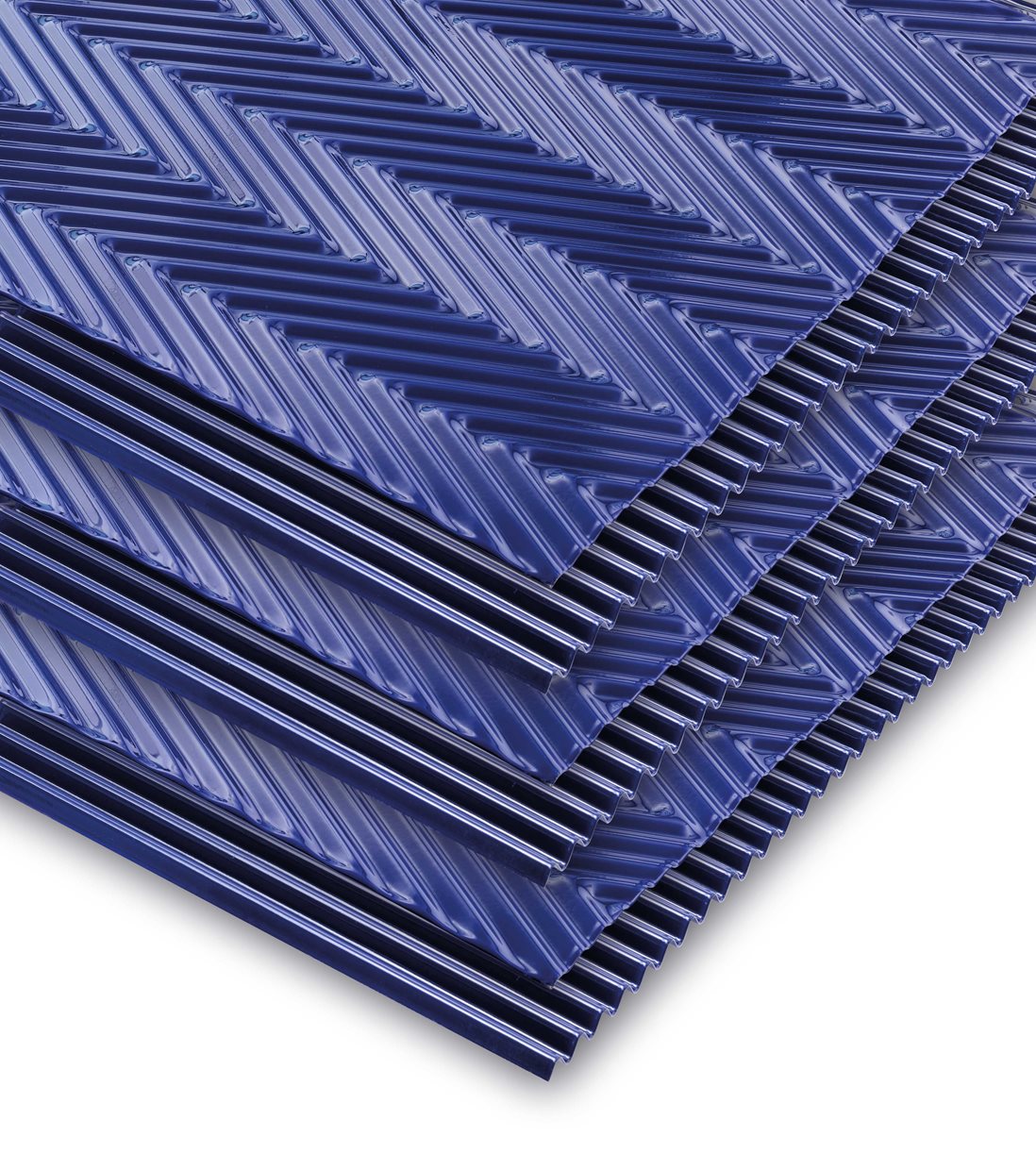

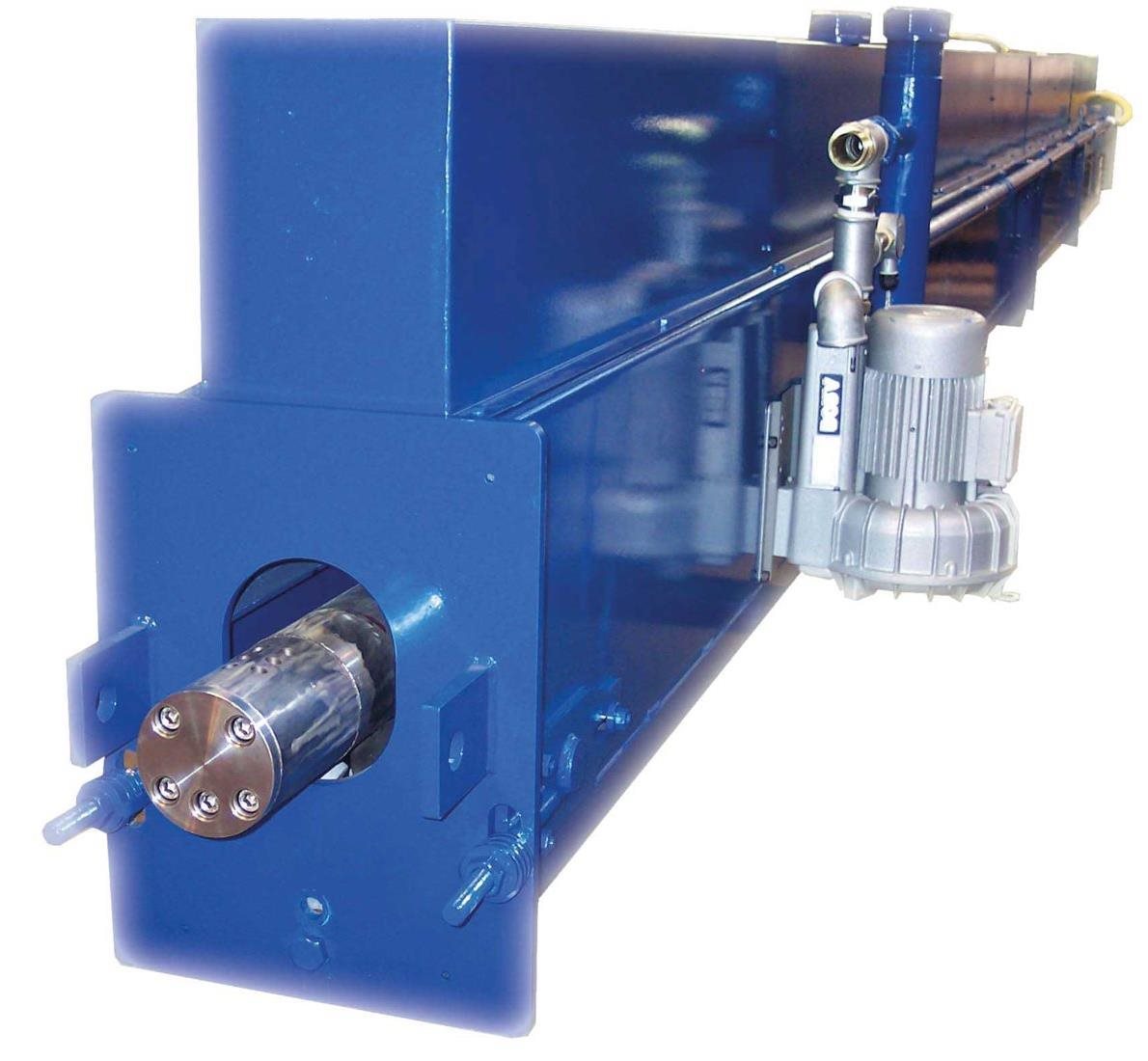

Sellos de contacto

Los sellos de contacto flexibles para intercambiadores de calor rotativos son un método para minimizar los espacios de fuga directa entre el extremo caliente del rotor y las placas sectoriales, que separan los flujos de aire y gas.

Los sellos estándar fallan debido a la flexión constante, por lo tanto, Howden llevó a cabo un extenso programa de desarrollo para optimizar los sellos de contacto para aplicaciones adecuadas que proporcionan reducciones de fugas importantes. Dado que los sellos funcionan mejor en situaciones donde los espacios son pequeños y uniformes, la reducción de fugas puede mejorarse aún más combinándose con placas sectoriales parabólicas.

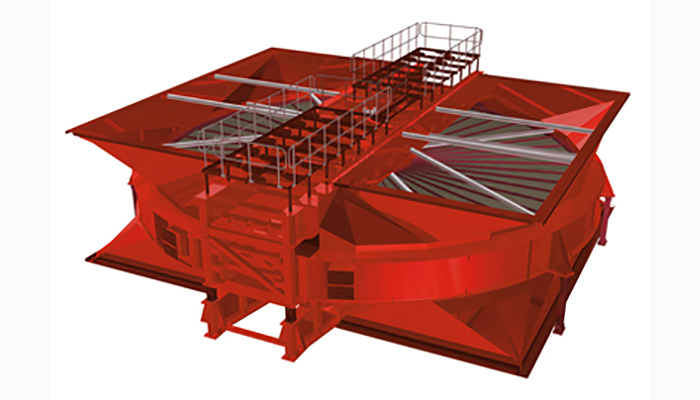

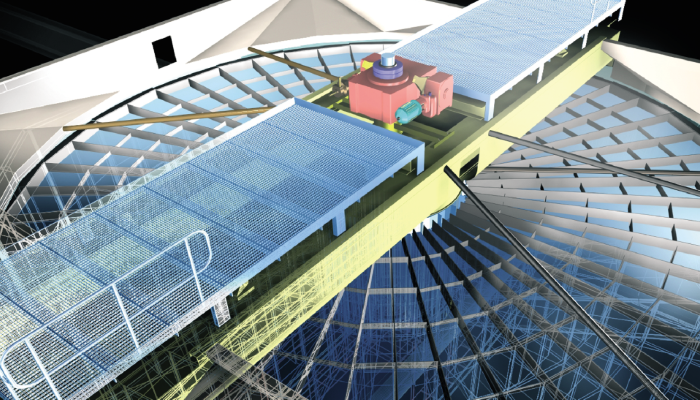

Placas sectoriales parabólicas

El mayor escrutinio medioambiental y la demanda de niveles más altos de eficiencia han llevado a Howden a desarrollar placas sectoriales parabólicas (patente pendiente) para su uso con nuestros calentadores.

Las placas sectoriales de extremo caliente están diseñadas con rigidez variable para deformarse parabólicamente cuando se accionan, para coincidir con la forma del rotor de funcionamiento deformado. Esto minimiza el espacio de fuga del extremo caliente.

Las placas sectoriales parabólicas Howden no solo reducen la potencia del ventilador de tiro en la planta, sino que también disminuyen el flujo de masa de gas hacia el equipo de reducción de emisiones en el sector downstream.

Solicite documentación

Solicite una cotización

Solicite una cotización

Envíe una consulta por correo electrónico

Envíe una consulta por correo electrónico

Encuentre nuestras sucursales

Encuentre nuestras sucursales

Únase a nuestro equipo

Únase a nuestro equipo